WITTENSTEIN at SPS 2022

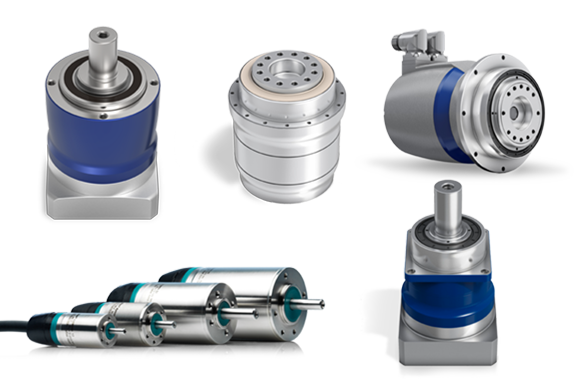

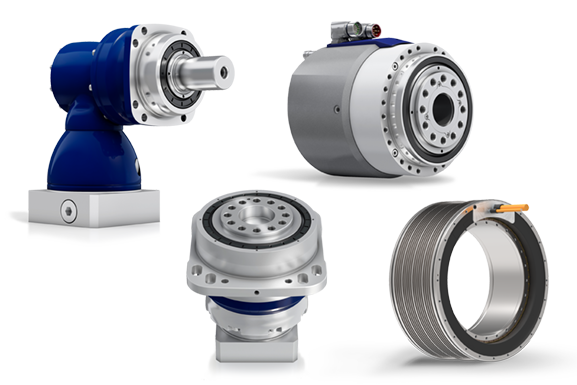

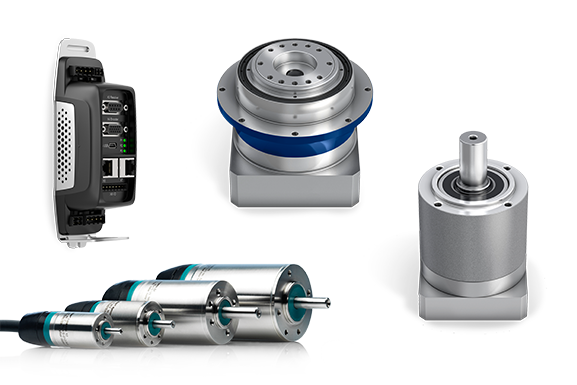

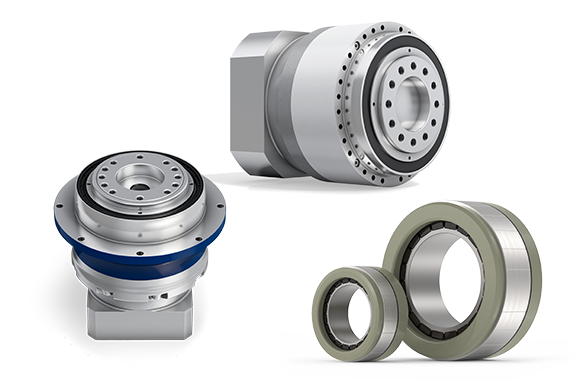

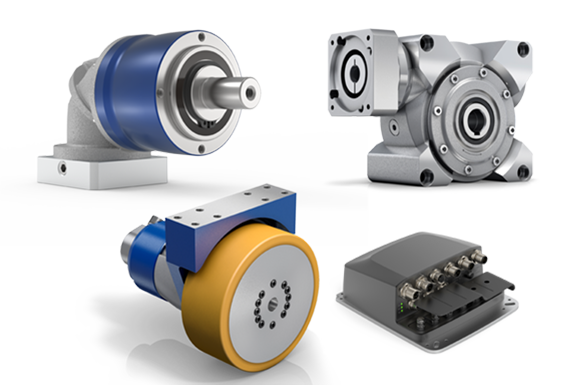

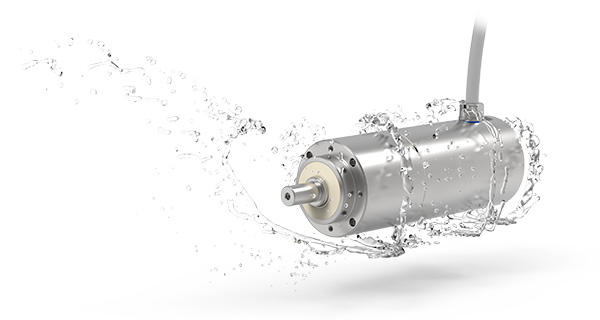

In Nuremberg, the WITTENSTEIN group has shown industry-specific drive solutions for packaging machinery, dosing systems, machine tools and automation technology as well as robotics, handling systems and intralogistics. Innovations in our core business of mechatronic drive technology and the future market for digitalized components and solutions have been presented there under the motto STAY AHEAD TOGETHER.

Industry-Specific Drive Solutions

Contact us

You would like to learn more about our product highlights or industry-specific drive solutions? Or would you like to have a personal exchange with our experts? Please don't hesitate to contact us.