All parts of a machine must work reliably over the entire service life. Our focus is on the quality and durability of all WITTENSTEIN products. This minimizes the total cost of ownership of the entire application.

- Expertise

- Fields of competence

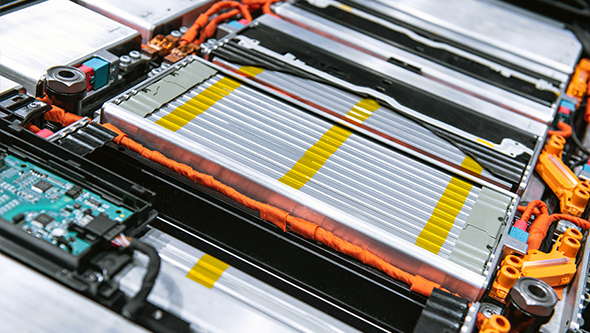

- Battery Production

Battery Production

Maximum throughput with a high level of economic efficiency and flexibility is a key factor in the battery manufacturing industry. These requirements can be met by the extensive product portfolio of the whole WITTENSTEIN group and its professional expertise. From cell production to cell and pack assembly, and right through to general automation technology, we take your application to the next level with our innovative solutions. This ensures that the demand for reliability and maximum precision over the entire period of use is met in combination with excellent reproducibility.

Fields of Application

Cell Manufacturing

Cell manufacturing involves various steps in the preparation of raw materials. It is where the foundation is laid for sophisticated energy storage systems. Therefore, process reliability is necessary to ensure a high standard of production quality.

WITTENSTEIN provides best-in-class products covering a wide range of requirements. Different sizes of planetary and right-angle gearboxes with low backlash and high power density as well as compact actuator solutions guarantee consistent results regardless of where the products are used. We supply companies all over the world for all types of manufacturing steps, from slurry mixing to calendering to coating, to name but a few. In particular, our TP+ gearboxes and TPM+ actuators deliver impressive performance in various classes, combining maximum performance with a space-saving design thanks to the flange output shape. With the WITTENSTEIN Galaxie® gearboxes and actuators, we can achieve maximum rigidity with zero backlash over the entire service life. Moreover, the easy-to-integrate and compact cyber® kit line frameless servo motors from WITTENSTEIN cyber motor offer a high degree of efficiency with a large torque/speed range and low maintenance requirements.

Assembly of Battery Cells and Packs

Cell assembly is a multifaceted part of battery manufacturing in which the individual components are assembled, finished and tested. An efficient machining solution is the key to reliable output rates at a top-quality level.

WITTENSTEIN products meet the requirements for dynamics and precision that are necessary for the assembly and testing of battery cells and packs. Our CP and NP gearboxes combine high performance with economic aspects in order to be competitive on the world market for energy storage systems. For applications that require maximum precision, the unique functional principle of WITTENSTEIN Galaxie® gearboxes and actuators represents a high-quality solution with no maintenance effort but a multitude of added value. In addition, our cyber® kit line frameless servo motors with low speed fluctuations and high precision are suitable for many use cases within the cell manufacturing process. Furthermore, we offer an industrial small servo drive system which can be used for dispensing and dosing applications, for example. This means that we have a wealth of experience, not only in the field of motion control but also in filling, sealing and gluing applications. The servo motors of the cyber® dynamic line and servo drives of the cyber® simco® line are ideally suited for such applications.

Automation Technology

The handling of battery cells and packs is an essential part of the whole production process. In every application, the workpiece needs to be positioned before and after it is processed. The cells also have to be transported to storage locations during production steps such as formation or aging. The higher the level of automation, the more productively and reliably a plant can work. Powerful, efficient drive technology is therefore essential to optimize cycle times.

WITTENSTEIN has many years of experience in the field of automation technology and robotics. From common use cases to special requirements, such as high speeds and dynamics, right the way through to customized solutions, WITTENSTEIN provides the perfect match for your requirements. Individual drive components, such as the DP+ planetary gearboxes designed specifically for delta robots, as well as the compact servo drive system cyber® iTAS® system 2 for automated guided vehicles (AGVs), consisting of actuator and the matching servo drive from the cyber® simco® line, open up a great many possibilities for you. Get in touch with our sales team and benefit from our expertise to find a suitable solution for your needs.

Battery Recycling

A circular battery economy is becoming more and more important. Sustainability throughout the value chain is increasingly in focus and being strengthened by legal regulations. For this reason, a growing number of companies are developing plants to disassemble packs and cells, and separate out the individual components.

WITTENSTEIN´s product portfolio provides many opportunities to optimize your application in terms of performance, compactness as well as durability. Exceptional working conditions do not pose a problem for our drive solutions. We develop and produce servo motors, gearboxes, electronics as well as complete mechatronic systems – including for critical use cases. Our HIGH TORQUE and HIGH SPEED gearbox lines are just one example of WITTENSTEIN´s flexibility within its existing product portfolio. Whether you are looking for an economic and scalable or a customized solution to your requirements – we take on any challenge!

Our product recommendations

cyber® kit line frameless servo motors

Contact us

Do you have a question about the field of battery production or do you require personal advice?

If so, please contact us directly. We look forward to hearing from you!