Hygienic and secure production

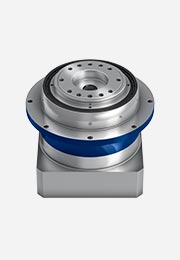

Corrosion protection is vitally important for quality and maintenance optimized production – to meet the rising worldwide demand for industrial cleaning technology. Our Corrosion Resistant and Hygienic Design products allow hygienic and sterile automation close to the process.

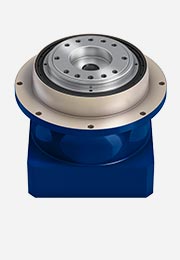

Hygienic Design

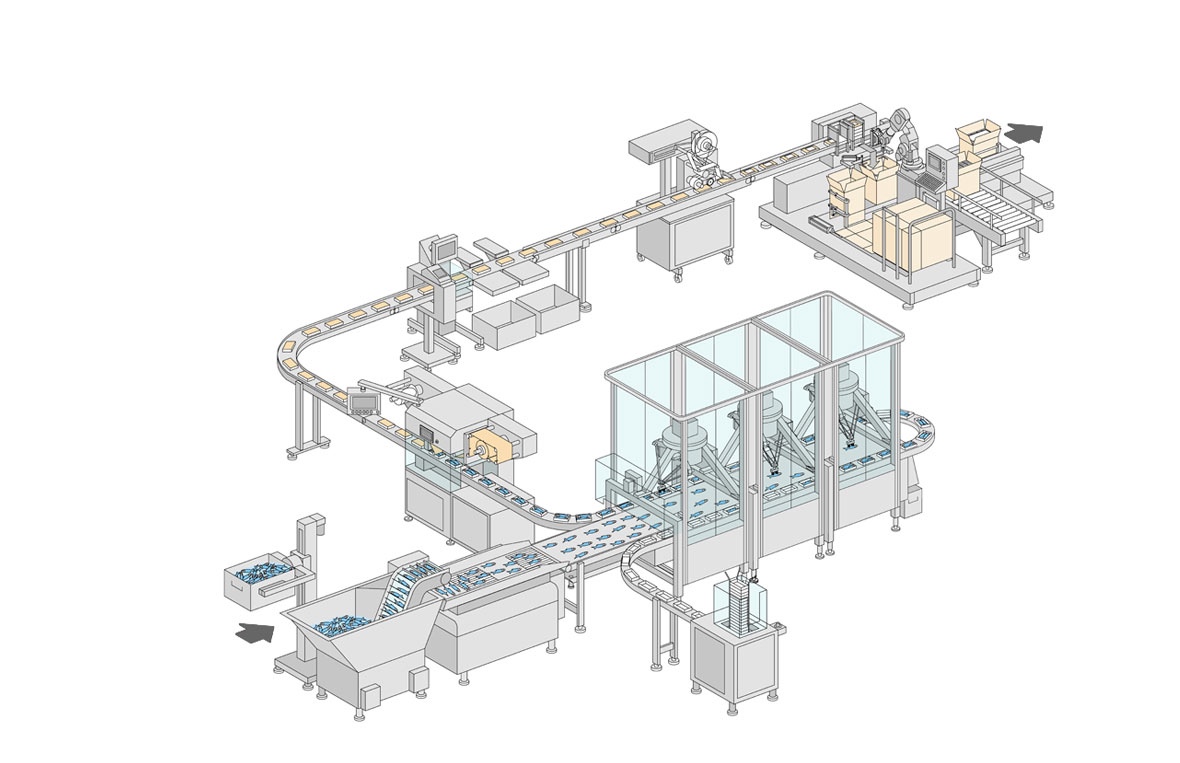

Integrated in the process

Applications

- CIP (cleaning in place) / SIP (sterilization in place)

- Delta robots

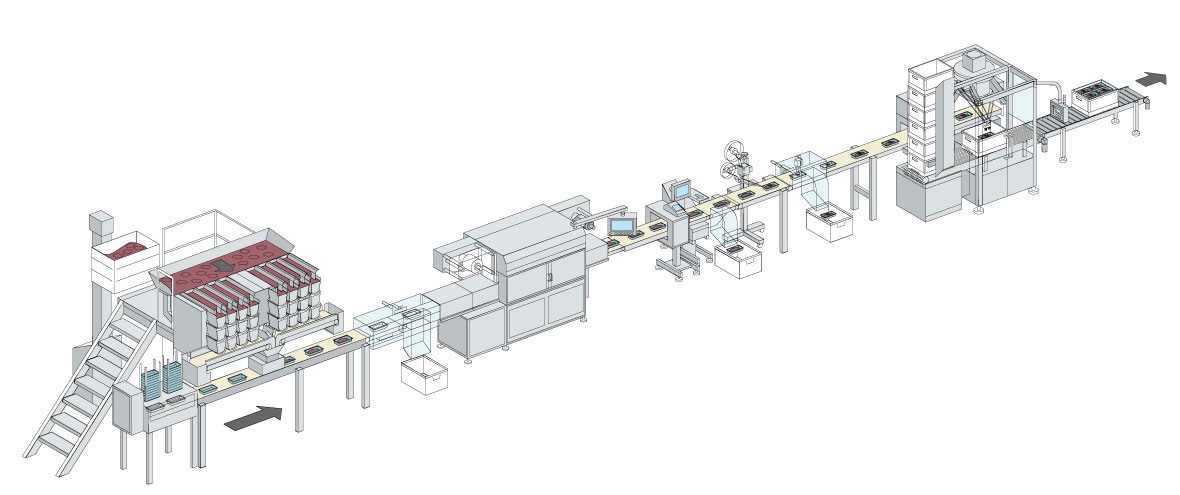

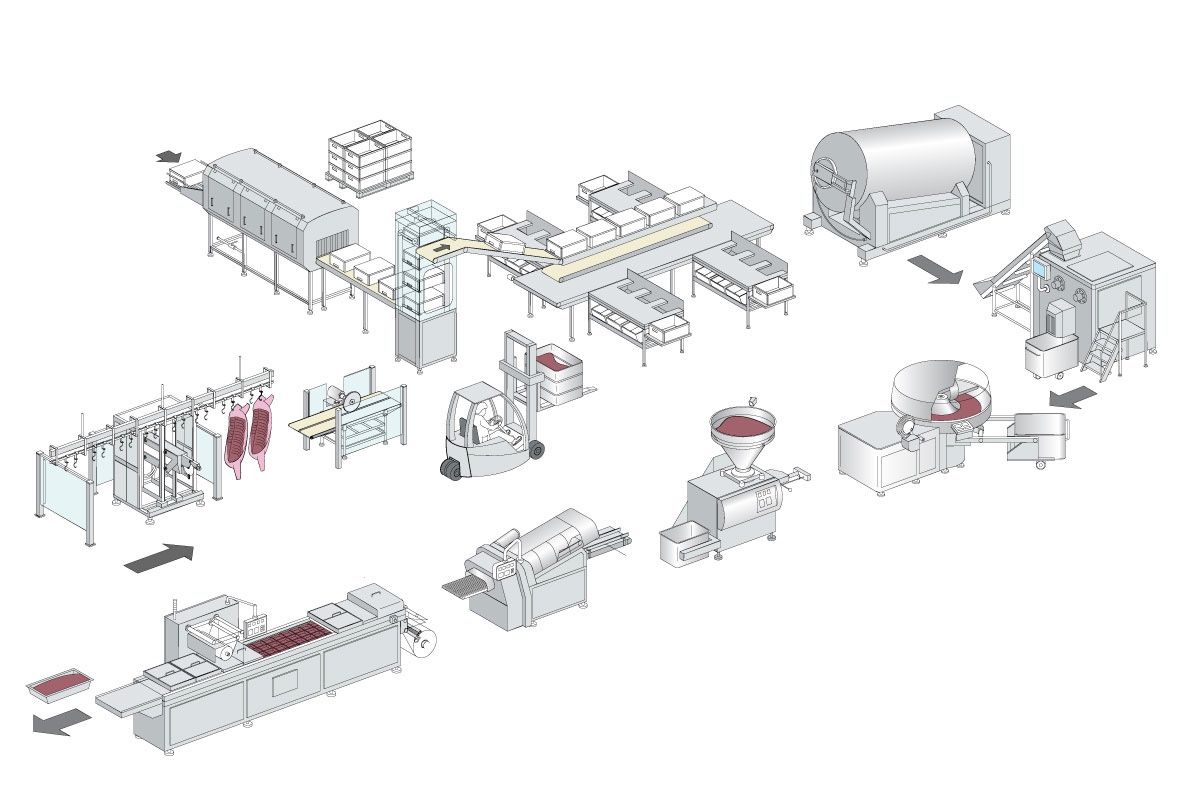

- Food industry (production, processing, packaging, filling)

- Cosmetics industry

- Pharma industry

- Process technology

Your Benefits

- Suited for hygienic and sterile production

- Direct contact with food allowed

- Fast, efficient and reliable cleaning

- Resistant to chemical cleaning materials and disinfectants

- Optimal sealing properties

- Maximum resistance to corrosion

- New design freedom because the drive is integrated directly in the process

Corrosion Resistant Design

Close to the process

Applications

- Environments with high humidity and cleaning process

- Environments where contact with food occurs

- Delta robots (e. g. with DP+ in corrosion resistant design)

- Solar industry

- Packaging industry

- Outdoor use

Your Benefits

- Protection against external influences (splash-proof to IP65)

- Protection against flash rust and oxidation

- Easy removal of fouling (germs, microorganisms, etc.)

- Stable processes thanks to WITTENSTEIN quality