The most compact hollow-shaft gearbox with the highest torsional rigidity: The new miniaturized Galaxie® gearbox

The miniaturized Galaxie® gearbox takes the proven principle of our classic Galaxie® a step further. The result: innovative kinematics enabling almost full surface contact during power transmission – in an extremely compact footprint. Thanks to this unique concept, the miniaturized Galaxie® performs significantly better than established gearbox types with the same diameter in almost all dimensions. It combines the highest levels of torsional rigidity, torque density and overload capacity with a very large hollow shaft and maintains zero backlash throughout its entire lifetime.

With these outstanding characteristics, the miniaturized Galaxie® is the ideal choice for applications where maximum precision and safety are decisive even though only limited space is available and a lightweight design is paramount – for example, in medical robots.

Contact us

The functional principle of Galaxie® new interpreted

Galaxie® in miniature

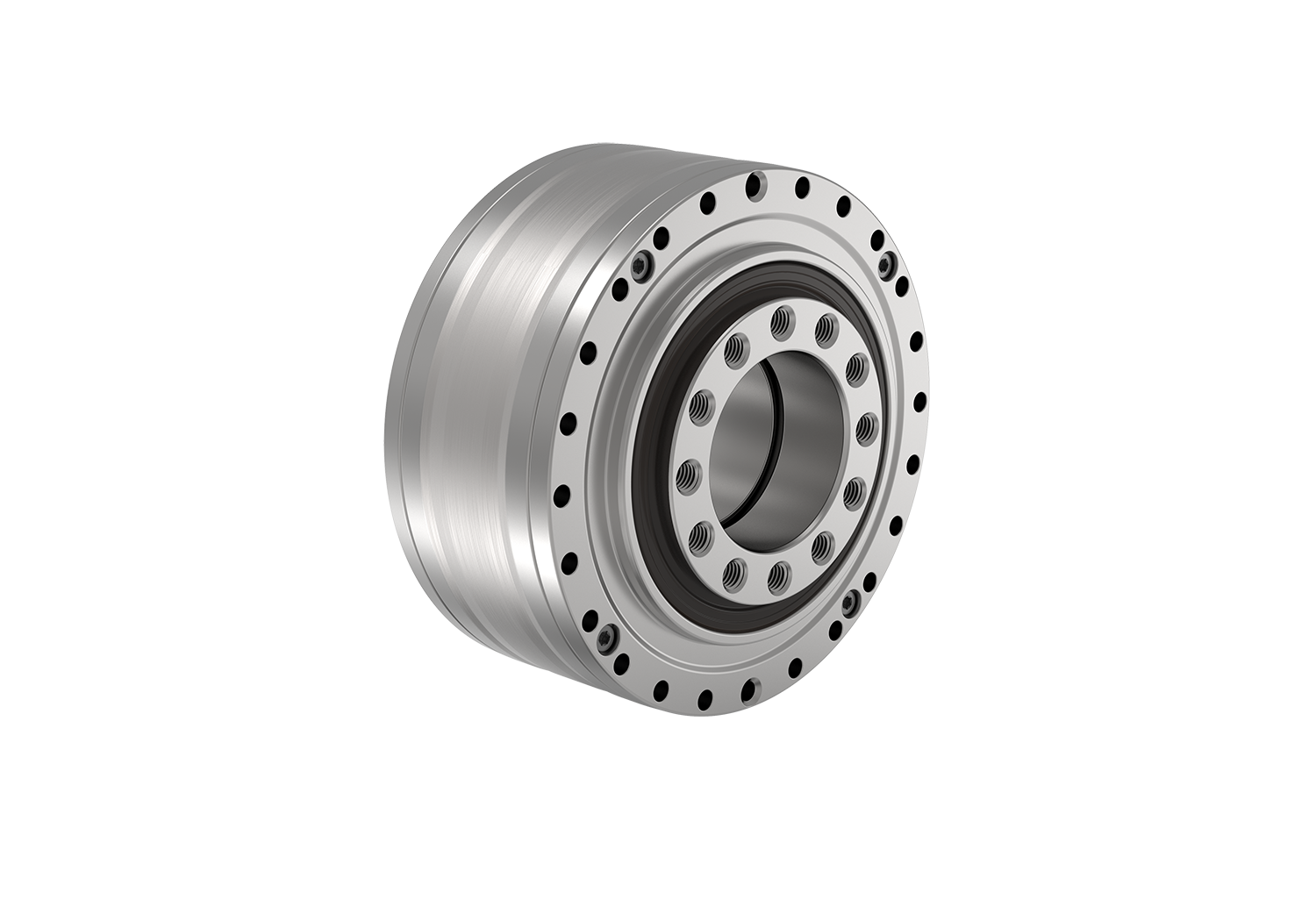

The miniaturized Galaxie® gearbox: it is characterized by maximum torque density and rigidity, excellent damping properties, absolute zero backlash and the largest hollow shaft.

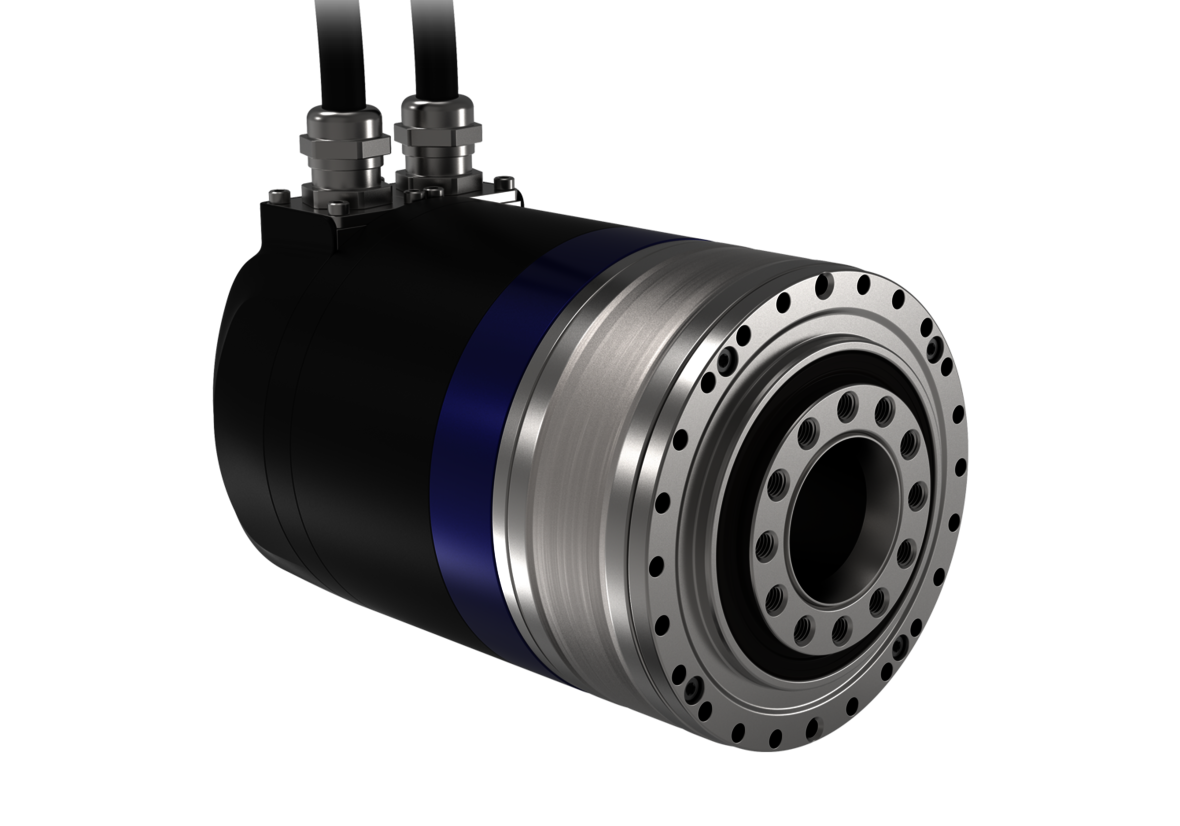

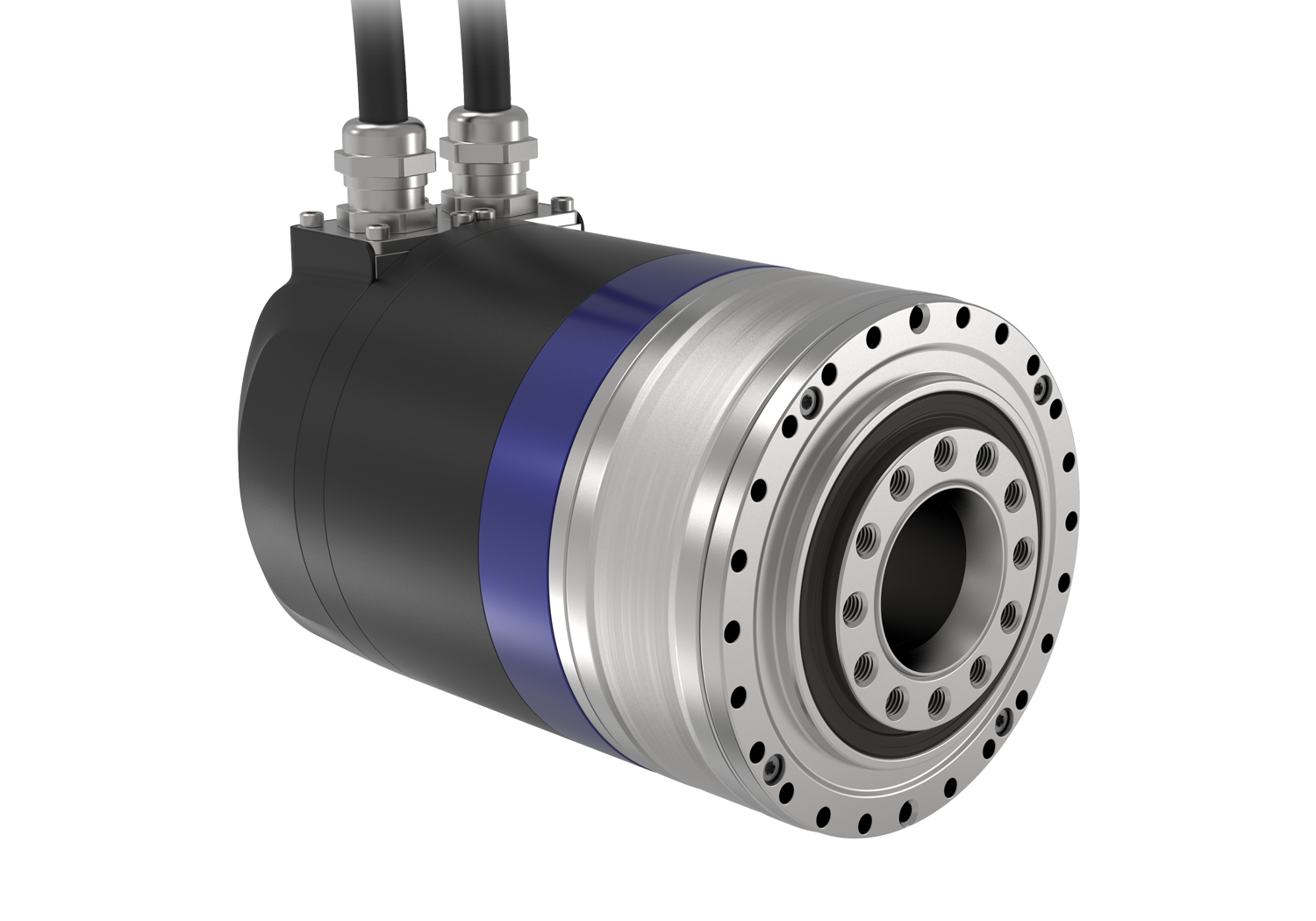

The miniaturized Galaxie® actuator: the combination of a miniaturized Galaxie® gearbox and a WITTENSTEIN cyber® motor kit line small with mit customized brake and feedback system

Galaxie® in miniature – Your benefits

More precision

The miniaturized Galaxie® extremely high torsional rigidity and higher dampening mean medical robots can perform surgical procedures much more precisely. Thanks to the higher machining precision, the quality of industrial products can likewise be increased. Absolute zero backlash likewise enables more precision in the application, e. g. when moving robot axes.

Space and weight savings

The miniaturized Galaxie® extremely high torsional rigidity and high torque density mean you can downsize the drive train or upgrade the application without any increase in footprint. The large hollow shaft can be used very efficiently, e. g. for wiring or for integrating media and / or components. The high torque density simultaneously permits the weight of the drive train to be reduced.

Maximum safety

The miniaturized Galaxie® extremely high torsional rigidity provides crucial safety reserves in case of overload. For example, there are no consequences if the surgeon accidentally touches the surgical robot’s arm. Media can be supplied through the large hollow shaft without any problem – and downtime due to broken or pinched cables is reduced to a minimum. The high torque density can serve as a safety buffer.

Faster and easier integration

The miniaturized Galaxie® can be installed quickly and easily in a variety of applications, and with the large hollow shaft the wiring is child’s play. Other features such as camera systems requiring extra wiring are thus very simple to integrate. The footprint is compatible with standard strain wave form (Harmonic Drive) gearboxes – an immense advantage.

Higher productivity

The miniaturized Galaxie® extremely high torsional rigidity allows higher acceleration rates and reduces vibration in the system. You also profit from faster and, above all, more accurate positioning because there is less oscillation time. The large hollow shaft minimizes cable breakage – the cause of more than 90% of all robot downtime.

Technical data

Our newest member of the Galaxie® family

Motor

Depending on the gearbox size, cyber® kit line 85-20 or kit line 85-40 can be integrated

Electrical connection

Direct cable outlet, straight or angled integral socket version available

Encoder

BISS-C, EnDat2.2, Hiperface or even the integration of a dual encoder are possible

Connection to the application via

Output flange (standard) or additional housing flange (customized) possible

Operating voltage

Windings for 48 or 560 V DC are available depending on the application and servo controller

Brake

A spring-loaded brake can be integrated to match the power of the motor

Miniaturized Galaxie® Gearbox

Gearbox with zero backlash, maximum rigidity and torque density make the actuator unique in its class

Galaxie® in miniature compared to usual strain wave gearboxes

- 40 % higher maximum torque Tmax

- 30 % higher torque density

- 3-times higher rigidity over complete torque range

- Up to 50 % larger hollow-shaft

- Zero backlash over service life

Applications

Downloads

Contact us

Is there anything you'd like to know about Galaxie® in miniature? Do you require personal advice?

If so, please contact us directly. We look forward to hearing from you!